As a Warehouse Management System (WMS) solution provider, UBCT empowers your business to seamlessly adapt to ever-changing market conditions. Leveraging modern capabilities, our WMS streamlines processes, automates warehouse functions, optimises resources, and ensures the timely execution of events.

Whether you operate a single distribution centre or a multi-distribution network, our flexible solution can be rapidly configured to meet your specific requirements. Achieve unparalleled operational excellence with UBCT’s warehouse management solution, designed to elevate logistics efficiency and drive your business forward.

Warehouse Automation Solutions with AMR

Our turnkey and extensible systems ensure the safe and efficient movement of everything, from parts to pallets, within warehouses, production facilities, and distribution centres.

What is an Autonomous Mobile Robot (AMR)?

Autonomous Mobile Robots (AMRs) are highly advanced robots capable of independent movement in their environment without human supervision or pre-set paths. Equipped with sensors, AMRs efficiently perform tasks, taking the shortest routes and avoiding collisions with fixed and moving obstacles.

Unlike other technologies like AGVs, AMRs offer unmatched flexibility in choosing the safest and best task routes. Integrated with warehouse control systems, AMRs optimize processes and workflows, enabling tasks such as transporting, picking, and placing goods. This collaboration with operators enhances productivity and safety, allowing more valuable tasks to be carried out in the warehouse.

AMRs can function for extended durations without requiring frequent charging and will automatically return to a charging station, eliminating the need for manual intervention in routine maintenance. By employing autonomous mobile robots, warehouse operations can expand as needed, freeing human workers to focus on more valuable tasks and mitigating the risks of relying on short-term seasonal labour.

SMART BI and Digital Twin

Smart BI is a data-driven visualisation dashboard that enables manufacturing facilities to customise their production line effortlessly. It represents the ultimate objective of Industry 4.0 in manufacturing, seamlessly unifying platforms from production equipment to collect, organize, and activate data.

The key strength of Smart BI lies in its ability to visualise complex data sets in a user-friendly and easily interpretable manner. With access to real-time data and stored information, Smart BI simplifies performance customisation and beyond, making it easier to target and identify bottlenecks in the production process. This level of insight provides the freedom to optimise the entire production line, maximising efficiency and productivity.

Moreover, Smart BI empowers decision-makers with the ability to make data-driven choices promptly. With a deeper understanding of performance metrics and process dynamics, plant managers can proactively allocate resources, plan production schedules, and adapt to changing demands swiftly. This level of agility ensures that manufacturing facilities remain competitive and responsive in today’s fast-paced business landscape.

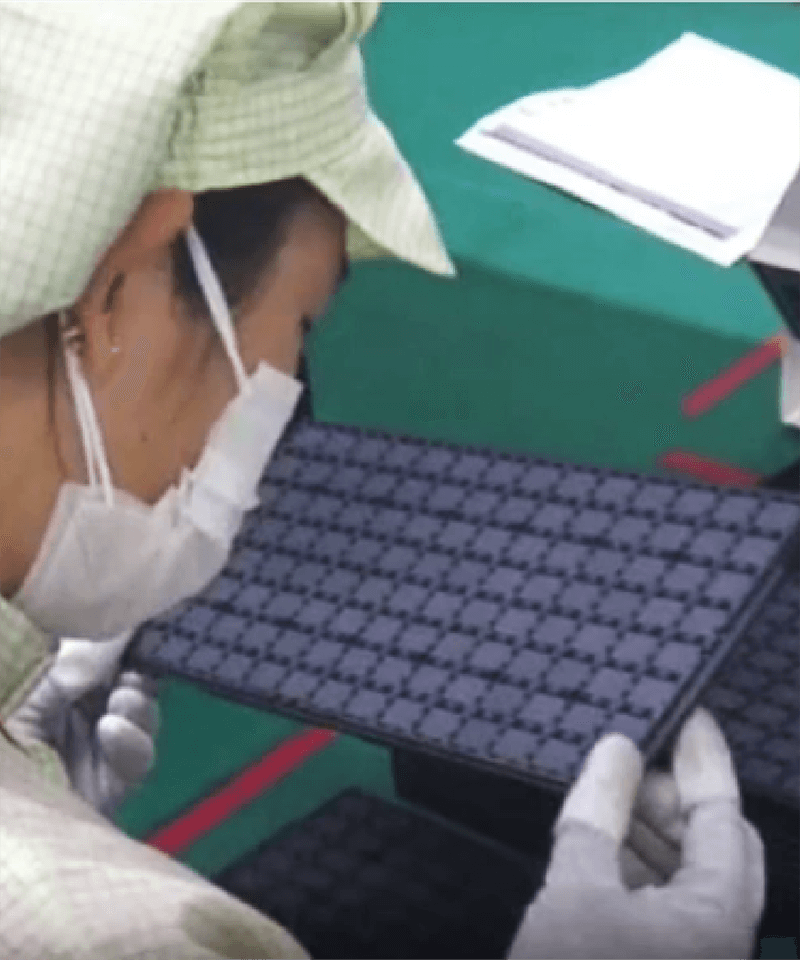

AI Smart Industrial Monitoring (AI)

Our AI Recognition Technology is a versatile platform capable of facial, object, text, and speech recognition, offering various applications. Integrated with Information Analysis (AI) and Artificial Intelligence (AI), our RTMIP opens up incredible possibilities by automating processes that once relied solely on human sight and hearing.

With real-time 24-hour sensory detection, our system efficiently tracks specific tasks through live surveillance footage.

Many individuals seek benefits in three main areas:

- Enhanced intelligence to elevate manufacturing accuracy, throughput, and yields while lowering expenses.

- Increased agility to facilitate swift product design and prototyping, improved performance analysis, and a versatile and resilient supply chain.

- Enhanced sustainability to diminish energy costs and minimize environmental impact.

Experience the power of AI-driven monitoring, enhancing operational efficiency and precision in industrial settings. Trust in our advanced technology to transform your operations and drive success.

Automated Packaging Solutions

Automated packing systems have evolved from singular machines that automate individual steps in the packaging process to integrated solutions that seamlessly handle the entire packaging process. This advanced level of automation enables effortless adjustment of quantities and facilitates handling products in various box sizes.

While automatic packaging systems may appear costly compared to traditional manual processes, it is essential to consider the concealed expenses linked to manual packaging operations. In the long run, automated packaging equipment can prove cost-effective, offsetting expenses through savings in both costs and labour. Automated packaging enables you to efficiently handle the growing influx of online orders, even during peak periods.

With automated packing solutions, businesses can optimise their packaging operations for increased efficiency and adaptability, ensuring a streamlined and error-free packaging process. Businesses worldwide enjoy the advantages of a smooth packing process, cutting labour expenses while minimizing box volume and corrugate usage.

Operational

Efficiency

Maximize inbound and outbound processes, and enhance stock and truck turnaround ratios for optimal solutions.

24/7

Operation

Operates 24/7 with no labor requirements.

Minimize Handling

Errors

Eliminate product mishandling clusters, save time, and reduce operating costs.

Consistent Product Quality

Warehouse automation improves productivity efficiency without compromising on quality.